We are proud exclusive distributor of Microfinishing Equipment in Canada.

Did you know?

Any company can incorporate Micro-finishing and Superfinishing into their operation.

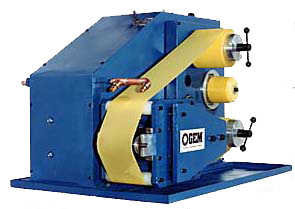

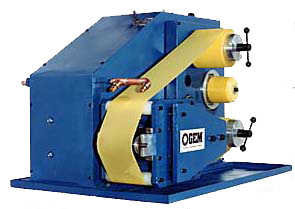

Attachments, which can be mounted on any lathe or cylindrical grinder, are available for Microfinishing rolls and other large parts. These attachments are available from a 2" abrasive width up to 24" abrasive width. The most popular are 4" and 8" models. Many styles of production machines are also available, including Thru Feed and Plunge Centerless, Center Driven, Turnkey Roll Finishing and custom machines built to a customer' specification.

Virtually any size part can be microfinished.

Companies are finishing fuel injector parts, transmission components, shock absorber rods, valve stems and many other small components. Paper mills are microfinishing rolls that can be up to 60" in diameter and 400" long. Very large copper foil drums and Yankee dryer drums are also finished using this process.

Lapping is a low-velocity abrading finishing process that removes controlled, very small amounts of material.

Microfinishing consists of rotating a work piece at relatively slow speeds. An abrasive cutting media is then applied to the part while oscillating at lower amplitudes and higher frequencies.

Microfinishing (superfinish) is used on High Velocity Oxy-Fuel Coatings (HVOF), Tungsten Carbide, Ceramics, Hard Coating, Chrome Plating, Bearing Steel, Forged Steel, Chilled Iron, Cast Iron, Stainless Steel but also medium and soft materials including Epoxy, Nylon, Copper, Aluminum, Soft and Hard Rubber.

Contact us at: 450.692.8203

© 2022 - PDE Microfinishing